Industrial News

The Hygienic Advantages of Aluminum Pharma Tubes

Views : 627

Update time : 2024-11-25 11:32:12

In the world of pharmaceutical and cosmetic packaging, maintaining hygiene and product safety is paramount. Consumers rely on packaging to protect the integrity of their medications, skincare products, and other personal care items. Pharmaceutical aluminum tubes have gained prominence as a preferred packaging option due to their hygienic advantages over other materials. Let’s look at the reasons why aluminum pharma tubes stand out in terms of hygiene and how they contribute to ensuring product safety and consumer well-being.

1. Barrier Properties of Aluminum

Protection Against Contamination

Aluminum boasts excellent barrier properties that effectively shield the contents of ointment tubes from external contaminants. Unlike some other packaging materials, such as plastics, aluminum is impermeable to gases, moisture, and light. This impermeability prevents contaminants, such as bacteria, dust, and air, from entering the tube and compromising the integrity of the product. By providing a protective barrier, aluminum pharma tubes help ensure that the contents remain pristine and free from contamination throughout their shelf life.

Preservation of Product Integrity

In addition to protecting against contamination, aluminum's barrier properties contribute to the preservation of product integrity. By creating a sealed environment, aluminum pharma tubes help maintain the efficacy and stability of pharmaceutical and cosmetic formulations. This is particularly important for sensitive medications and skincare products that can degrade when exposed to air, moisture, or light. Aluminum's ability to safeguard the contents of ointment tubes ensures that consumers receive products that are potent, safe, and effective, enhancing their overall experience and satisfaction.

2. Tamper-Evident Features

Seal Integrity

One of the key hygienic advantages of aluminum pharma tubes is their tamper-evident features. Aluminum tubes are typically equipped with seals or closures that provide visual evidence of tampering. These seals may include breakable bands, foil seals, or screw caps that must be broken or removed before the product can be accessed. Tamper-evident features ensure that consumers can easily identify if a tube has been opened or compromised, allowing them to make informed decisions about the safety and integrity of the product.

Consumer Confidence

The presence of tamper-evident features on pharmaceutical aluminum tubes instills confidence in consumers regarding the safety and authenticity of the product. Knowing that their medications or skincare products are protected by tamper-resistant packaging gives consumers peace of mind, especially when purchasing over-the-counter medications or products from unfamiliar brands. By prioritizing tamper-evident features, manufacturers demonstrate their commitment to consumer safety and build trust with their target audience, ultimately enhancing brand reputation and loyalty.

3. Ease of Cleaning and Sterilization

Resilience to Cleaning Agents

Aluminum pharma tubes are easy to clean and sterilize, thanks to the material's resilience to harsh cleaning agents. Unlike some plastics that may degrade or absorb cleaning solutions, aluminum remains unaffected by most cleaning agents commonly used in pharmaceutical and cosmetic settings. This allows for thorough cleaning of the tube's surface, eliminating any potential contaminants or residues and ensuring hygienic storage of the product.

Compatibility with Sterilization Methods

Moreover, aluminum pharma tubes are compatible with various sterilization methods, including autoclaving, gamma irradiation, and ethylene oxide sterilization. These sterilization techniques are commonly employed in pharmaceutical manufacturing facilities to ensure the safety and sterility of medical and cosmetic products. Aluminum's ability to withstand sterilization processes without compromising its structural integrity makes it an ideal choice for packaging materials in sterile environments.

4. Environmental Considerations

Recyclability

In addition to their hygienic advantages, aluminum pharma tubes offer environmental benefits due to their recyclability. Aluminum is one of the most recyclable materials, with the ability to be recycled repeatedly without losing its quality or properties. Recycling pharmaceutical aluminum tubes helps conserve natural resources, reduce energy consumption, and minimize waste sent to landfills. By choosing aluminum packaging, manufacturers can support sustainable practices and contribute to a circular economy.

Reduction of Single-Use Plastic

Furthermore, aluminum pharma tubes play a role in reducing the reliance on single-use plastic packaging. As the world grapples with plastic pollution and its environmental impact, there is a growing push to replace single-use plastics with more sustainable alternatives. Pharmaceutical aluminum tubes offer a viable solution, providing a durable and recyclable packaging option that helps reduce plastic waste and mitigate environmental harm.

Beyond expectation

Aluminum pharmaceutical tubes offer a range of hygienic advantages over other packaging materials, making them a preferred choice for pharmaceutical and cosmetic products. From their barrier properties that protect against contamination to their tamper-evident features that ensure product safety, aluminum tubes prioritize hygiene and consumer well-being. Additionally, their ease of cleaning and compatibility with sterilization methods further enhance their suitability for sterile environments. Moreover, aluminum pharma tubes contribute to environmental sustainability through their recyclability and role in reducing single-use plastic.

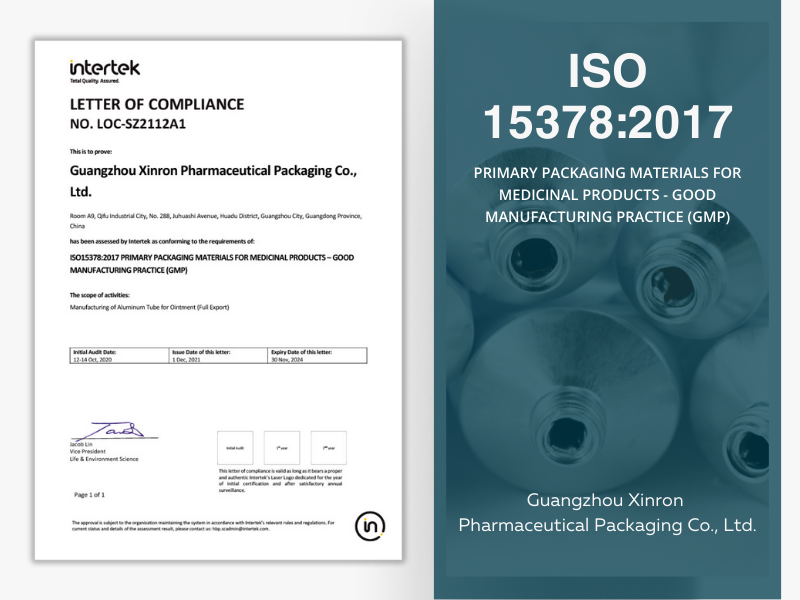

We can embrace hygienic and environmentally friendly packaging solutions for a safer and more sustainable future. Guangzhou Xinron Pharmaceutical Packaging Co., Ltd. is pharma tube manufacturer, offering aluminum pharmaceutical tubes in 13.5 mm, 16 mm, 19 mm, and 22 mm diameters, ideal for medical and cosmetic purposes. Please contact us for inquiries: sales@xinrontube.com

1. Barrier Properties of Aluminum

Protection Against Contamination

Aluminum boasts excellent barrier properties that effectively shield the contents of ointment tubes from external contaminants. Unlike some other packaging materials, such as plastics, aluminum is impermeable to gases, moisture, and light. This impermeability prevents contaminants, such as bacteria, dust, and air, from entering the tube and compromising the integrity of the product. By providing a protective barrier, aluminum pharma tubes help ensure that the contents remain pristine and free from contamination throughout their shelf life.

Preservation of Product Integrity

In addition to protecting against contamination, aluminum's barrier properties contribute to the preservation of product integrity. By creating a sealed environment, aluminum pharma tubes help maintain the efficacy and stability of pharmaceutical and cosmetic formulations. This is particularly important for sensitive medications and skincare products that can degrade when exposed to air, moisture, or light. Aluminum's ability to safeguard the contents of ointment tubes ensures that consumers receive products that are potent, safe, and effective, enhancing their overall experience and satisfaction.

2. Tamper-Evident Features

Seal Integrity

One of the key hygienic advantages of aluminum pharma tubes is their tamper-evident features. Aluminum tubes are typically equipped with seals or closures that provide visual evidence of tampering. These seals may include breakable bands, foil seals, or screw caps that must be broken or removed before the product can be accessed. Tamper-evident features ensure that consumers can easily identify if a tube has been opened or compromised, allowing them to make informed decisions about the safety and integrity of the product.

Consumer Confidence

The presence of tamper-evident features on pharmaceutical aluminum tubes instills confidence in consumers regarding the safety and authenticity of the product. Knowing that their medications or skincare products are protected by tamper-resistant packaging gives consumers peace of mind, especially when purchasing over-the-counter medications or products from unfamiliar brands. By prioritizing tamper-evident features, manufacturers demonstrate their commitment to consumer safety and build trust with their target audience, ultimately enhancing brand reputation and loyalty.

3. Ease of Cleaning and Sterilization

Resilience to Cleaning Agents

Aluminum pharma tubes are easy to clean and sterilize, thanks to the material's resilience to harsh cleaning agents. Unlike some plastics that may degrade or absorb cleaning solutions, aluminum remains unaffected by most cleaning agents commonly used in pharmaceutical and cosmetic settings. This allows for thorough cleaning of the tube's surface, eliminating any potential contaminants or residues and ensuring hygienic storage of the product.

Compatibility with Sterilization Methods

Moreover, aluminum pharma tubes are compatible with various sterilization methods, including autoclaving, gamma irradiation, and ethylene oxide sterilization. These sterilization techniques are commonly employed in pharmaceutical manufacturing facilities to ensure the safety and sterility of medical and cosmetic products. Aluminum's ability to withstand sterilization processes without compromising its structural integrity makes it an ideal choice for packaging materials in sterile environments.

4. Environmental Considerations

Recyclability

In addition to their hygienic advantages, aluminum pharma tubes offer environmental benefits due to their recyclability. Aluminum is one of the most recyclable materials, with the ability to be recycled repeatedly without losing its quality or properties. Recycling pharmaceutical aluminum tubes helps conserve natural resources, reduce energy consumption, and minimize waste sent to landfills. By choosing aluminum packaging, manufacturers can support sustainable practices and contribute to a circular economy.

Reduction of Single-Use Plastic

Furthermore, aluminum pharma tubes play a role in reducing the reliance on single-use plastic packaging. As the world grapples with plastic pollution and its environmental impact, there is a growing push to replace single-use plastics with more sustainable alternatives. Pharmaceutical aluminum tubes offer a viable solution, providing a durable and recyclable packaging option that helps reduce plastic waste and mitigate environmental harm.

Beyond expectation

Aluminum pharmaceutical tubes offer a range of hygienic advantages over other packaging materials, making them a preferred choice for pharmaceutical and cosmetic products. From their barrier properties that protect against contamination to their tamper-evident features that ensure product safety, aluminum tubes prioritize hygiene and consumer well-being. Additionally, their ease of cleaning and compatibility with sterilization methods further enhance their suitability for sterile environments. Moreover, aluminum pharma tubes contribute to environmental sustainability through their recyclability and role in reducing single-use plastic.

We can embrace hygienic and environmentally friendly packaging solutions for a safer and more sustainable future. Guangzhou Xinron Pharmaceutical Packaging Co., Ltd. is pharma tube manufacturer, offering aluminum pharmaceutical tubes in 13.5 mm, 16 mm, 19 mm, and 22 mm diameters, ideal for medical and cosmetic purposes. Please contact us for inquiries: sales@xinrontube.com

Related News

Why Aluminium Hand Cream Tubes Are the Best Choice

Feb .25.2025

When it comes to packaging hand creams, product developers have several options—plastic tubes, glass jars, pump bottles, and aluminium collapsible tubes. Among these, aluminium hand cream tubes stand out as a superior choice due to their excellent protect

7 Benefits of Using Aluminum Pharmaceutical Tubes for Cosmetics

Nov .21.2024

In the competitive world of cosmetics, packaging plays a crucial role in ensuring product safety, efficacy, and consumer appeal. Aluminum pharmaceutical tubes have become a popular choice for cosmetic packaging due to their numerous benefits. Here are sev

Why Aluminum Ointment Tubes are Preferred for Pharmaceutical Packaging

Jul .18.2024

In the pharmaceutical industry, the packaging of products is just as critical as the formulation itself. Aluminum ointment tubes have emerged as the preferred choice for packaging a variety of pharmaceutical products, including ointments, creams, and gels

Ensuring Quality and Compliance: Inside Xinron Tube's ISO 15378 Certified Aluminum Tube Manufacturing

Apr .03.2024

In the pharmaceutical industry, ensuring the safety and integrity of medicinal products is paramount. From manufacturing to packaging, adherence to stringent standards is non-negotiable. This is where ISO 15378 comes into play. Let's take a closer look at